komodo® Vertically Stirred Mills

Unlock Hidden Value: The Future of Energy-Efficient Fine Particle Comminution

komodo® Vertically Stirred Mills (VSM™) deliver class-leading performance in fine and ultrafine grinding, optimising your entire metallurgical process flow circuit. Reduce operating costs and increase recovery with our advanced comminution solutions.

- Compact Installation Footprint

- High Quality Parts = Lower downtime

- Lowest maintenance time & safety risk

- Lowest OPEX

- Plug & Play VSM™ PLC Control -> MillCruize® operational software®

Are High Energy Costs Limiting Your Profitability?

In today’s economic climate and increasing energy costs, overcoming these challenges has become easier with vertically stirred mills and often saves clients up to 80% of their energy bill compared to more traditional milling circuits.

Grinding Inefficiencies Limiting Your Profitability?

Many of our clients want:

- Lower energy consumption,

- Lower operational costs,

- Increased accuracy with P80 particle size distribution

- Ease of maintenance

We tick these boxes and go the extra mile to ensure these investments remain sustainable by offering addition of MillCruize® Stirred Media Milling & circuit asset management software.

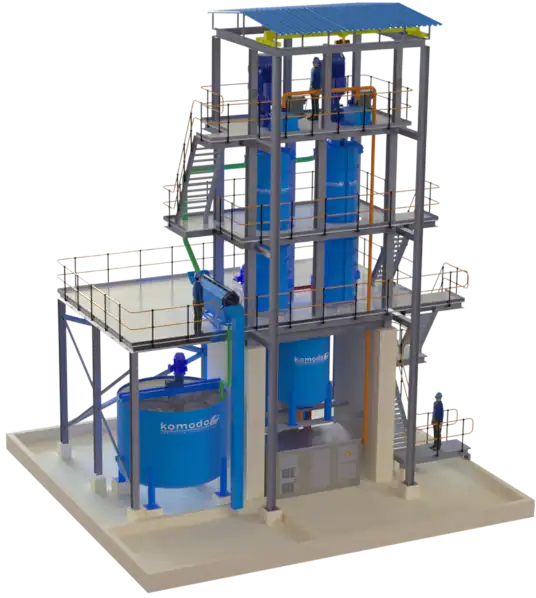

komodo® VSM™ - More Than Just a Mill.

Engineered by Huyser Industries, a recognized provider of vertically stirred mill technology, the komodo® VSM™ Vertically Stirred Mill range is the definitive answer to modern mineral processing challenges. Delivering world-class fine grinding performance, ensuring optimal particle size liberation while attaining lowest OPEX.

Discover our

range

We move beyond simply supplying a vertically stirred mill; we provide a complete, optimized solution tailored to your unique operational needs, from initial consultation to after-sales service.

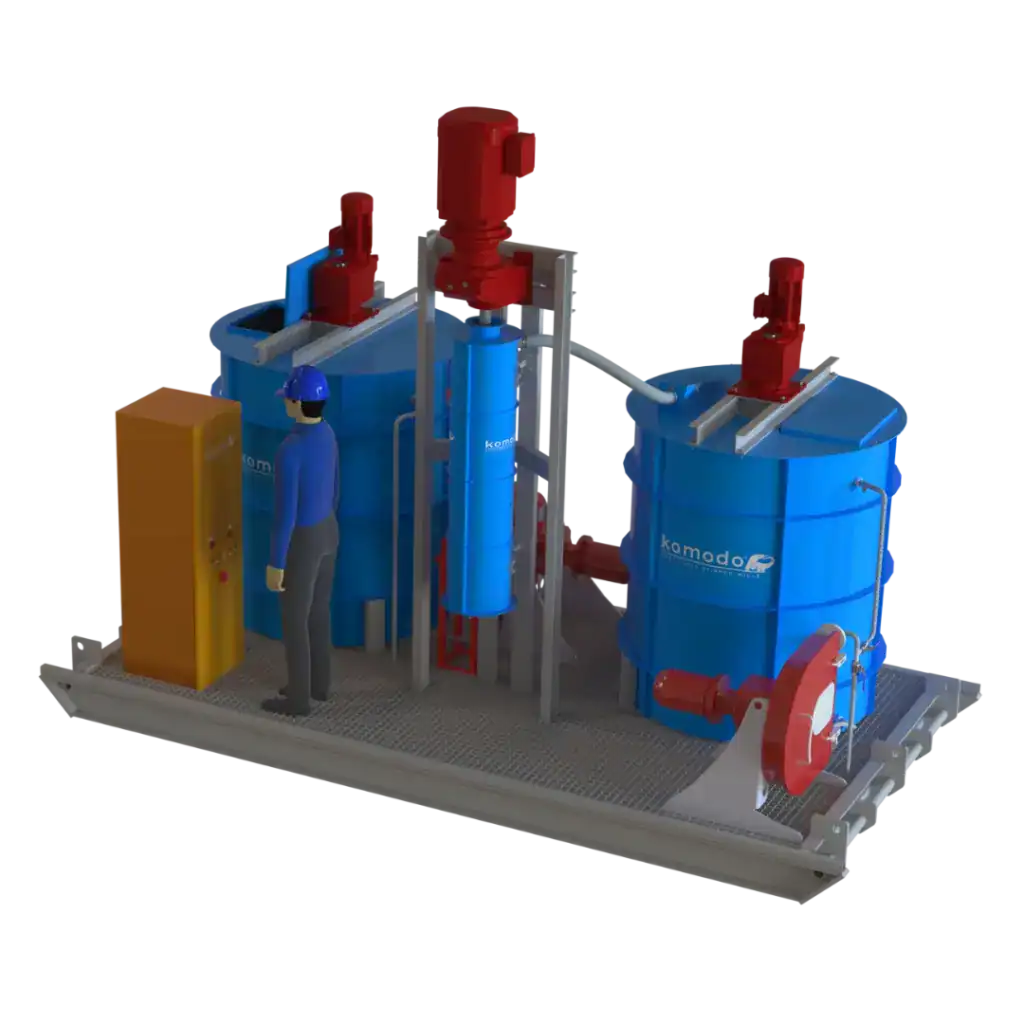

komodo® VSM™ powerLAB 10

Our PowerLAB 10 system provides metallurgists with accurate insight into ore’s grinding characteristics, ensuring reliable scale-up and confident selection of industrial equipment.

komodo® VSM™ powerPiLOT 120

Our PowerPiLOT 120 systems are designed to give you a clear, reliable understanding of your ore’s grinding characteristics, ensuring precise “scale-up” and confident industrial equipment selection.

komodo® Vertically Stirred Mills

Engineered for exceptional grinding efficiency, the komodo® VSM™ delivers industry-leading performance with lower energy consumption by up to 60%, long-lasting wear parts, and PSD selection results in fine to ultra-fine regrinding.

Unmatched OPEX & Energy Efficiency

Up to 80% Reduction in your energy consumption compared to traditional ball mills. The komodo® VSM™ range’s innovative design, featuring proprietary vertical stirrer and liner designs, minimizes energy waste and wear costs. This, directly translates to lower operating costs and a more sustainable comminution solution.

The komodo® VSM™ innovative design, featuring an advanced vertical stirrer and drive train, features the following:

- Up to 80% reduction in energy consumption

- High-quality wear parts

- Low wear

- Reduced downtime

- Reduced maintenance shutdown periods

- Decreased maintenance times of which can be completed in 1 day

- Increased productivity resulting in reduced operational expenses

Optimised Performance & Recovery

Increase precise particle size distribution for optimised downstream processes.

With its efficient wet grinding action, the komodo® VSM™ reduces overgrinding and slimes formation with correct utilisation, resulting in higher throughput and improved mineral recovery.

Robust Design for Maximum Uptime

Designed and developed for the demanding conditions of the South African mining industry, our vertically stirred mills are engineered for reliability and longevity. From robust construction to high-quality wear components, the komodo® VSM™ proprietary design & patented Elastoloc (TM) internal liner system reduces wear rate, maintenance downtime, and delivers a substantially lower total cost of ownership than competing technologies.

komodo® vertically stirred mills are engineered to be reliable and durable. We build to the demanding conditions experienced within the mining industry by ensuring the highest quality materials are used.

Versatile Solutions Across a Range of Applications

Over 17 years, the komodo® VSM™ range has been meticulously developed and proven itself in hydro-mining & tailings retreatment applications in the harsh Bushveld Igneous Complex chromite ore bodies of Southern Africa.

Perfect for Tailings retreatment, hydromining and tertiary grinding stages in gold, copper, zinc, PGM, phosphates, lead, lithium and rare earth minerals processing.

Its versatility makes it the ideal choice for a wide variety of applications, including:

- Regrinding

- Polishing

- Attritioning

- Secondary / Tertiary grinding (CPL Range)

- Ultra-Fine Grinding

Contact komodo®mills today

Contact our team today for a personalized analysis of your production needs, and we’ll help you choose the komodo® Vertically Stirred Mill model perfect for your operation.